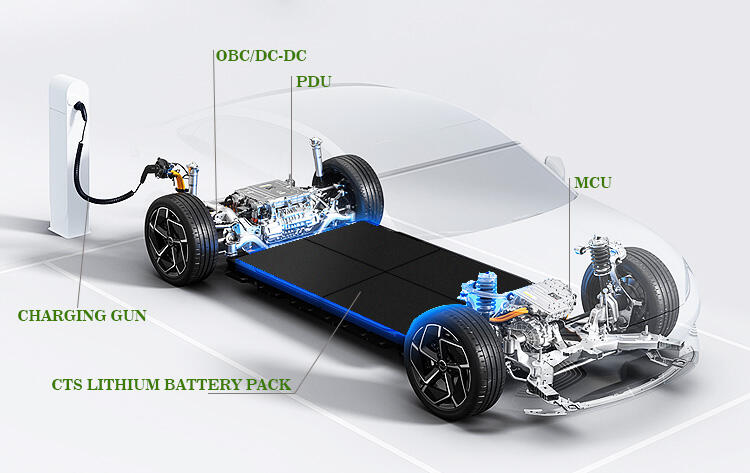

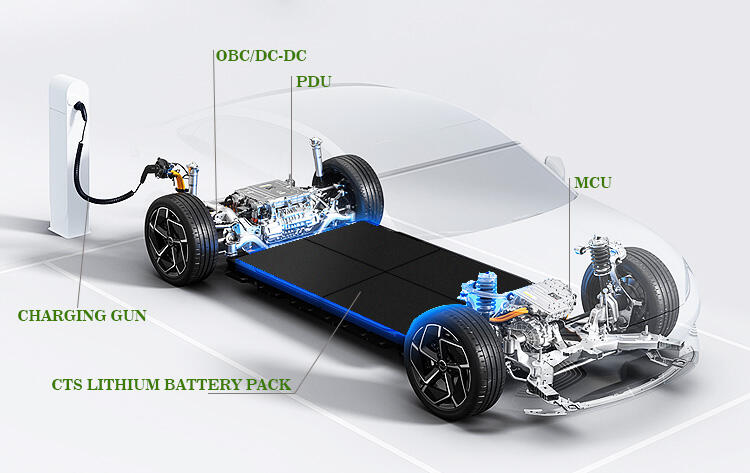

Sähköautojen akkujen, erityisesti Hunan CTS:n valmistamilla, toimii liitium-ioniteknologian periaatteiden pohjalta. Nämä akkujen ytimessä ovat liitium-ionisoluja, jotka CTS:n kokenut R & D -tiimi on valinnut niiden korkean energiatihersyysteen perusteella. Latauksen aikana, joka tapahtuu kun sähköauto liikkuu, liitium-iot liikkuvat negatiivisesta elektroodista (anoodi) positiiviseen elektroodiin (katoodi) elektrolyysikeskuksen kautta. Samalla elektronit virtaavat ulkoisessa piirissä, tuottamalla sähkövirtaa, joka käynnistää auton sähkömoottorin ja mahdollistaa ajoneuvon liikuttamisen. CTS:n sähköautojen akkujen keskeinen komponentti on Akkujen Hallintajärjestelmä (BMS). BMS toimii akun 'aivoina', seuraten ja ohjaen sen toimintaa monipuolisesti. Se varmistaa, että liitium-ionisolut toimivat turvallisissa jännitteessä, virtassa ja lämpötilassa. Esimerkiksi se estää ylikorjaamisen, mikä voi aiheuttaa muuttumattomia vahinkoja soluihin ja lyhentää akun elinikää, sekä yli-tyhjentämisen, mikä myös heikentää akun suorituskykyä ajan myötä. Kun on aika ladata akku uudelleen, ulkoinen virtalähde tarjoaa sähköenergiaa. Tämä energia aiheuttaa liitium-iot liikkumaan takaisin katoodista anoodiin, kääntämällä latausprosessin ja täyttämällä akun energian. CTS suunnittelee sähköautojen akkujensa edistyneillä termohallintajärjestelmillä. Koska äärimmäiset lämpötilat, sekä kuuma että kylmä, voivat vaikuttaa haitallisesti liitium-ionien suorituskykyyn ja elinikään, termohallintajärjestelmä pyrkii ylläpitämään optimaalista toimintälämpötilaa. Tämä varmistaa akun tehokkaan ja turvan toiminnan, maksimoimalla sen suorituskyken ja kestovuoden. Tiukilla laadunvalvontatoimilla, jotka noudattavat ISO9001:ää ja IATF16949 hallintojärjestelmiä sekä kansainvälisiä todistuksia, CTS:n sähköautojen akut tarjoavat luotettavaa ja tehokasta virtaa sähköajoneuvoille.